Frequently asked questions

I can see the device WIFI on my PC, but the UI does not populate.

The UI needs permission for private as well as public networks. Make sure you give those permissions when opening the UI for the first time.

Depending on the firewall settings, it can prevent access. Try disabling the firewall while connected to the device (remember to activate it again before going online!).

I place my device on the charger or try to start the WIFI with one mag swipe, but nothing happens.

Make sure your device is sufficiently charged. If the blue LED on the charger is still on, wait till it goes off, indicating that the device is now fully charged and try again.

If the device is still in logging mode (recording), you will need to stop the logging mode via 2 mag swipes before you can activate the WIFI mode.

Please check the WIFI Troubleshooting.pdf

How to fine tune the light trigger.

If you want to ‘fine tune’ and find the best value, then do a test run where you set both MIN values to 0. Start the cam a bit before dusk and place it under water in a horizontal position (like it would be on the animal). Let it record till its completely dark and then take it out and stop it. Download the data and look through the video to find out at what time it gets too dark. Based on the time, look up the corresponding light value at that time in the recorded data and use that value as MIN trigger value.

Max light values (both) MUST be at 65535!

If your device has LEDs, use the trigger value as MAX value for the LEDs (MIN value for LEDs has to be 0) and set the light trigger for the cam from 0 to 65535.

You can also use other magnets as long as they are not too strong.

Some fridge magnets work – usually not the ones having a thin (~ 1 mm) flat magnet, but the ones who have a bit more volume to them.

They do not need to be very strong.

When testing a magnet, move it slowly towards the location of the mag switch and stop as soon as you see it trigger the switch (= yellow LED comes on).

Remember how close you have to get to the switch and try to avoid getting closer than necessary.

Approach perpendicular towards the location of the mag switch. Do not slide the magnet ‘all over’ the surface of the device.

We are sorry, but due to security reasons only customers can register for their own CATS-Space.

Yes, we are happy to provide advice, service and modifications of non-CATS products.

Yes, we provide full support on all levels for any terrestrial project.

Yes, CATS is an international company which is active around the entire globe.

Yes, a large part of our business consists of special requests, which we develop from scratch.

– Do not trigger a clamp from the tagging gun in mid-air as this might send the clamp flying in all sorts of directions! Just use some folded cardboard as a ‘dummy fin’ and secure that in a vice or have someone hold it, so the clamp has a secured object to attach to.

If you manage to kill yourself with it, as a biologist this has to be considered ‘natural selection’!

-The clamps can bend. This means you can readjust the curvature of the arms. Just be careful not to put any pressure on the GTR! Easiest way to avoid this is to only bend the other arm. This also means that if you spread the clamp too far or leave it wide open for extended periods of time, it might not close to the original degree or not produce the force it used to when closed. If you want to do some dry testing, use one dedicated clamp so you do not potentially compromise the ones you want to deploy. When you load a clamp for deployment with a tag attached, but you are still waiting for a suitable animal or wont deploy straight away, just spread the clamp sufficiently for it to hold securely in the tagging gun. Only just before you are about to deploy it, spread it as far as necessary.

– There are different settings for the pin that goes through the coil (of the clamp) at the end of the tagging gun. This is to adjust the tagging gun for different clamp types but you can also vary the angle at which the clamp sits in the tagging gun a bit.

– The tagging guns can be completely dismantled for cleaning and lubricating. In particularly BEFORE AND AFTER using them in or near water. When using them on scuba it is recommended to rinse them thoroughly with freshwater straight afterwards and relubricate them with WD40 or alike.

Lanolin is also a good option – any lubricant that prevents corrosion and repels moisture.

All moving parts need to be lubricated. The part where you have to be most careful is the handle as that is not made from stainless steel. After every field trip it is recommended to completely take the device apart and rinse, clean and lubricate every bit.

First step is to remove the screw connecting the steel bar (coming out of the handle) to the inner tube shaft. Then you can remove the screws holding the handle in place. When opening the handle, there is a spring inside – make sure to open it carefully so you see how the spring is positioned. The rest should be self-explanatory.

I attached 2 pics of a rigged up suction cup release system which should give you an idea of how it works.

The tag in the pic is slightly different, but same basic system:

In the groove on top that goes across is where the GTR sits. It is held in place by cable ties.

The cable ties loop around the tag and are held in place by the holes on the side (prevent them from sliding forward or backwards).

Do not use those holes on the side as anchor point for the cable ties.

To actually ‘arm’ the unit and make the suction cups stick, the tubes coming from the suction cups must be kinked over so they are sealed and the ends passed through under the cable ties again so they are held down by them.

Once the GTR corrodes away, the cable ties loosen and the tubes can flip open, so water gets in and the suction cups release.

GTRs can be ordered from here:

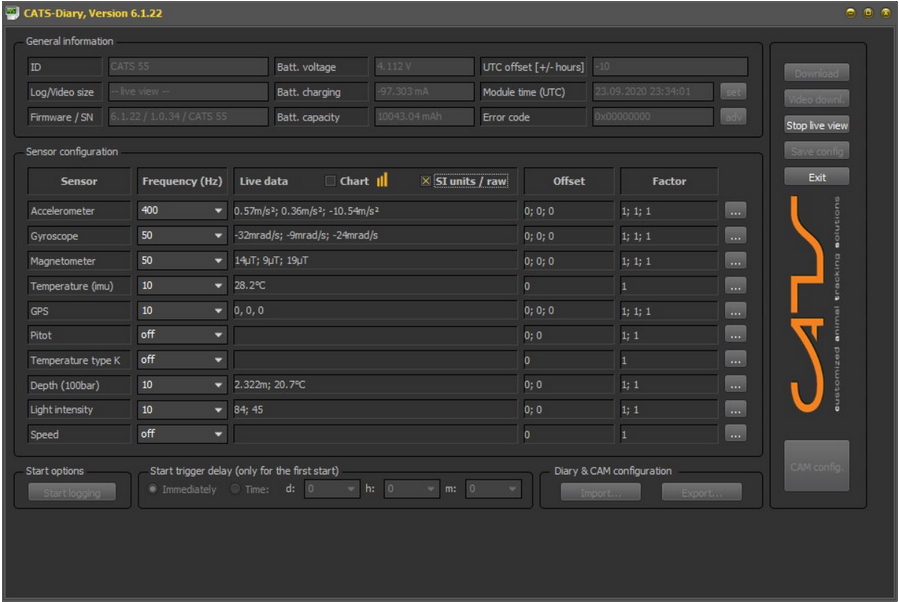

Turn on the CATS tag WiFi using the methods outlined in Part 1 (swipe once and wait for a solid blue light). Once the tag has successfully connected, click the “live view” button and wait for values to appear in the “live data” box.

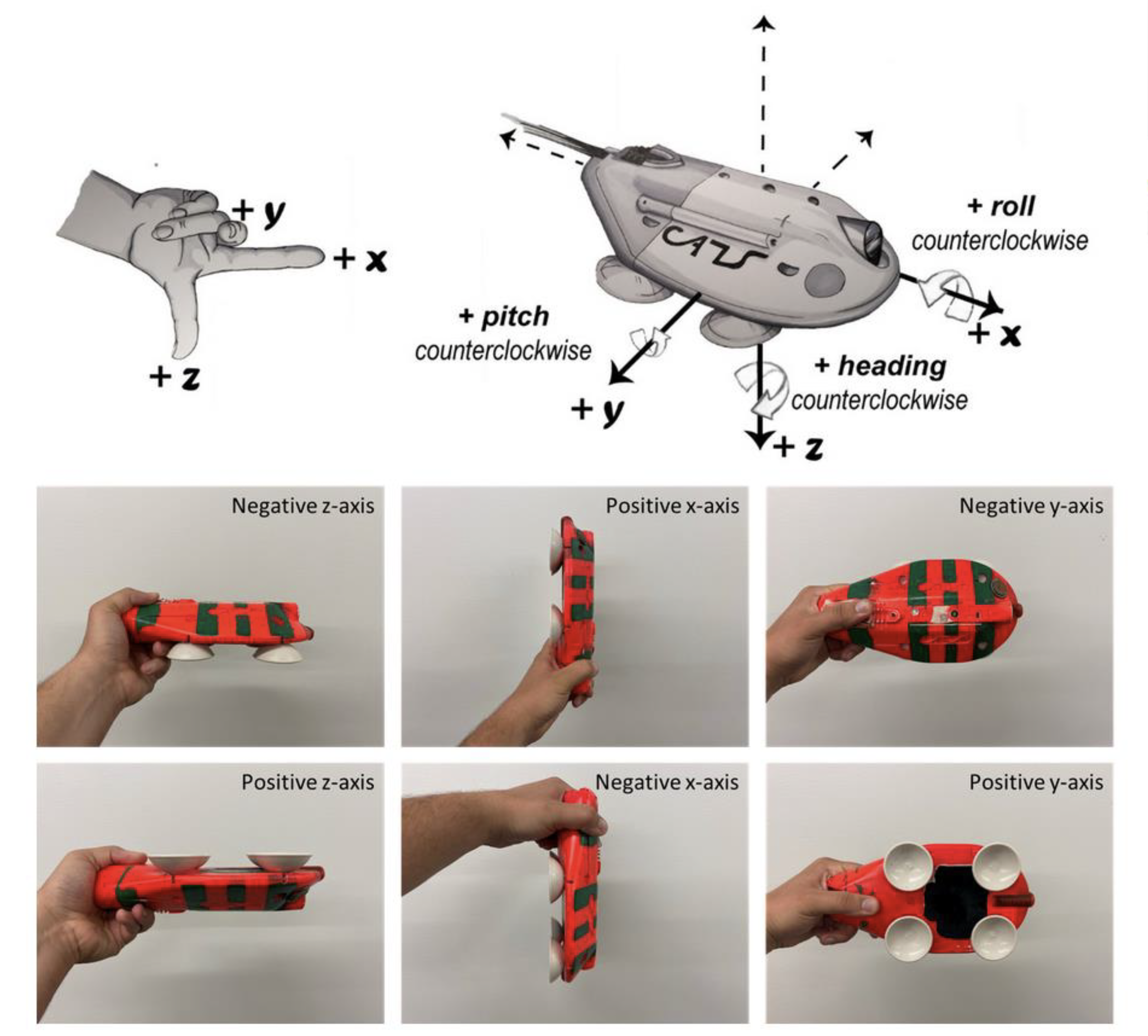

These values correspond to each of the three axes of the tag (x-axis, y-axis, and z-axis). When the tag is on a flat surface in a horizontal position, the x and y axes of the accelerometer should be close to O m/s2 and the z axis should be close to -9.8 m/s2 to correspond with the pull of gravity upon the tag. These orientations are shown in below.

For the magnetometer, the three axis will change in relation to magnetic north. When an axis is pointed towards the magnetic north pole (depending on your position on the globe, this point may be aimed downward and “inside” the earth), it will show its maximum (or minimum) value. See the image below for a compilation of these orientations.

For the gyroscope, rotational movement of the tag will determine values. Direction of the rotation will determine if the values are positive or negative. A rightward roll from a horizontal resting position should display positive x values, while a leftward roll from the same starting position should display negative x values. Rolling the tag upward along its short axis (camera rolling towards the sky and over backwards) should display positive y values, with a roll downward displaying negative y values. Finally, yawing (spinning) the tag to the left from a horizontal resting position should display negative z values, while yawing the tag to the right should display positive z values. See the image below for a schematic of these orientations.

It is possible that the order of these values will be different from the images shown above. If this is the case, the axis conventions for your tag may be different from those described above and you will want to check by running a series of quick diagnostic tests. For the accelerometer, some potential diagnostic movements include:

1. Flipping the tag onto its back and resting it flat on the table (Fig X; Bottom Left Image). This should constitute a change in the z-axis from negative to positive ~ 10 or vice versa, with no change in either the x or y axes.

2. Pointing the nose of the tag upwards or downwards, perpendicular to the table, should constitute a change in the x and z axes of the tag, with no change in the y axis (Fig X; Center Images). The x-axis will shift from -0 to either positive or negative -10 and the z-axis will shift from either positive or negative -10 to -0.

3. Rolling the tag until one side is in the air will constitute a change in they and z axes, with no change in the x-axis (Fig X; Right Images). The y-axis will shift from ~O to either positive or negative ~ 10 and the z-axis will shift from either positive or negative ~10 to ~0.

Be sure to perform diagnostic movements for all three of your inertial sensors (accelerometer, magnetometer, gyroscope) using the default axis conventions listed and shown above as a guide. While performing these diagnostics, assume that [x y z) is the default axis convention matrix. Any deviations from the default axis conventions should be reflected in your axis convention matrices. So, if you find that x values are positive when the tag is facing downward (center bottom image above), you would likely have an accelerometer axis convention of [-x y z]. If you found that they values are negative and the x and z values are zero when the tag is sitting flat and horizontal on a surface (top left image above), and also found that the z values are negative and x and y values are zero when the tag is turned with its right side down (top right image above), you would know that they and z axes are switched and you would likely have an accelerometer axis convention of [x z yJ.

Take some time to experiment with these diagnostics and get a sense for the axes of the tag. If you would like to see these values in a graphical forma~ check the -chart” box near the middle of UI screen next to the yellow graphical icon. This will produce a new window with three graphs showing a running waveform for each axis of the accelerometer, gyroscope, and magnetometer.